Your operations are continously evolving—

Heartland Automation is here to help

42%

of total task

hours

%

machines by 2022*

The Future of Jobs Report 2018

57%

of employers

%

to improve performance

& productivity*

Debunking myths and navigating new realities

14%

worldwide annual

growth

%

deployment*

velocity

accuracy

Errors are costly. Automated solutions reliably repeat critical tasks with precision, from conveyance to welding.

risk mitigation

Automated solutions that perform high-risk tasks or safely transport materials through your facility

AUTOMATION DRIVES PROFITABILITY

Improve the efficiency of your operations with automation

address labor shortfalls with automation

Reskill and repurpose employees for higher value tasks

Reskill and repurpose employees to other areas of the operation where their critical thinking skills can improve efficiency, reduce safety incidents, and improve quality.

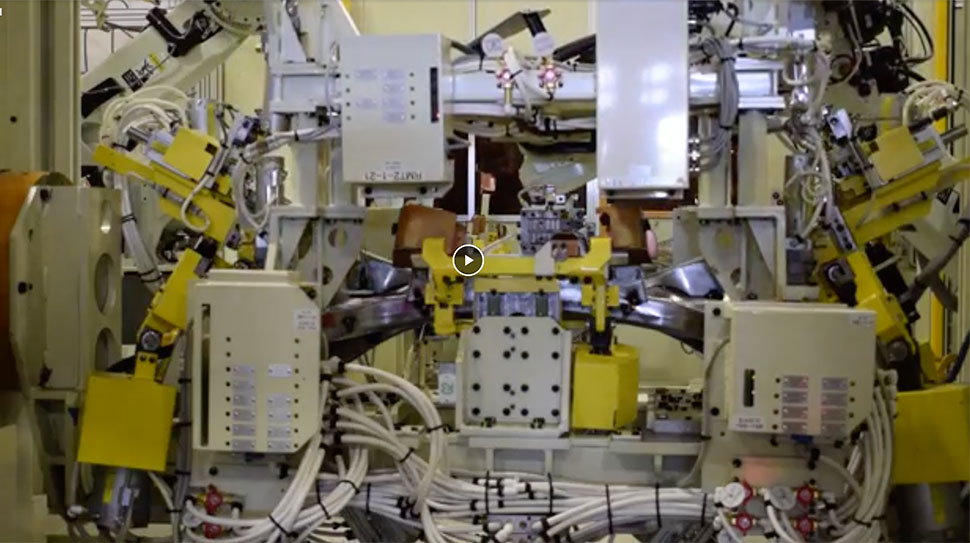

Industrial Automation

Achieve your lean manufacturing goals with reliable, industrial-strength automation

Deploy automated systems to complete high-risk, high-precision tasks such as welding, stamping, and sealing. Bespoke work cells are custom engineered to support your unique operational requirements.

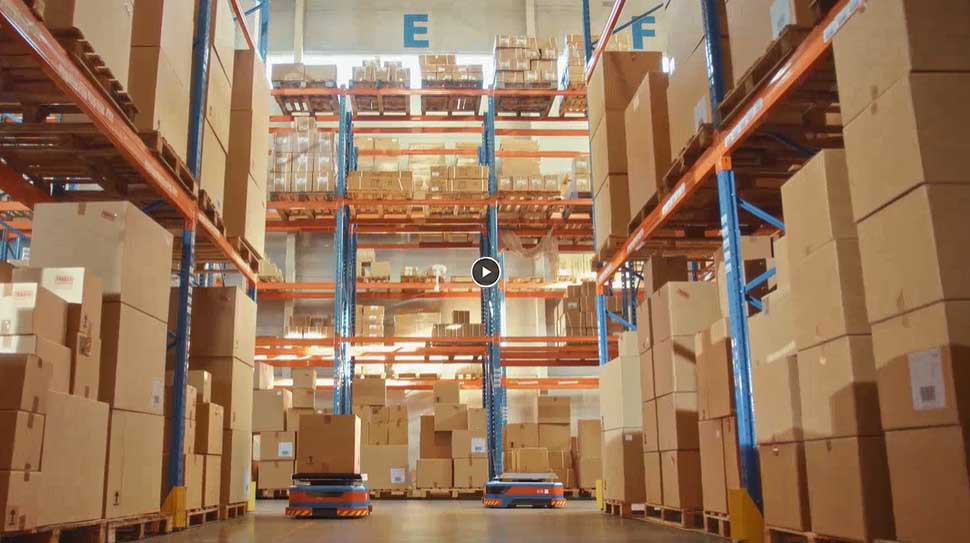

Automatic conveyance solutions and mobile robots streamline safe transport of heavy-payload materials between work cells or automate just-in-time delivery of materials to your lineside team. Automation manages repetitive material handling operations keeping employees safe and productive in their zones.

Peek inside the automated door welding work cell at a Tier 1 automotive manufacturing site.

warehouse automation

Meet today’s throughput demands by adding autonomous productivity

Watch an autonomous robots safely navigate in a high-traffic warehouse facility.

Crawl, Walk, Run